Why Change to Black Diamond

for Security Cylinders?

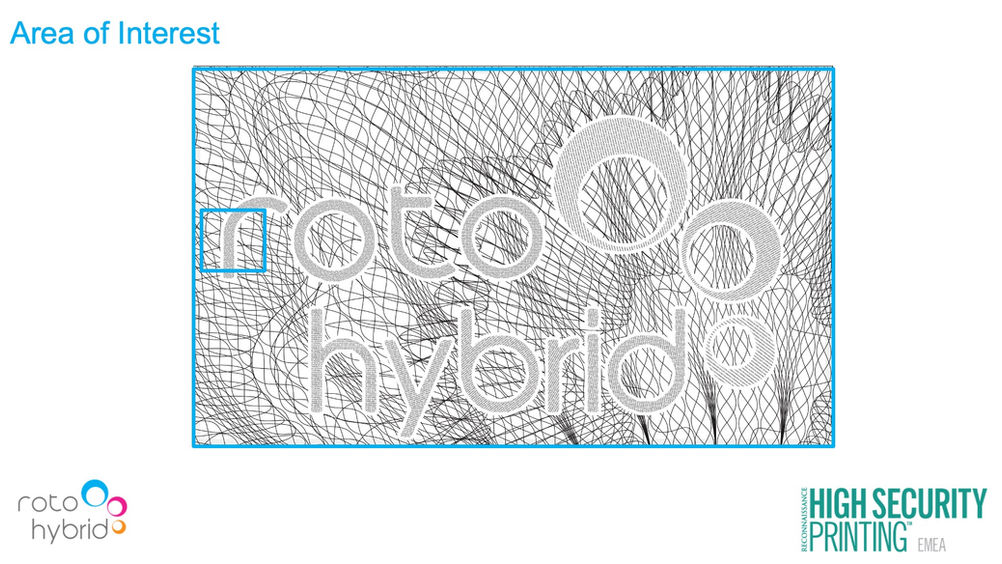

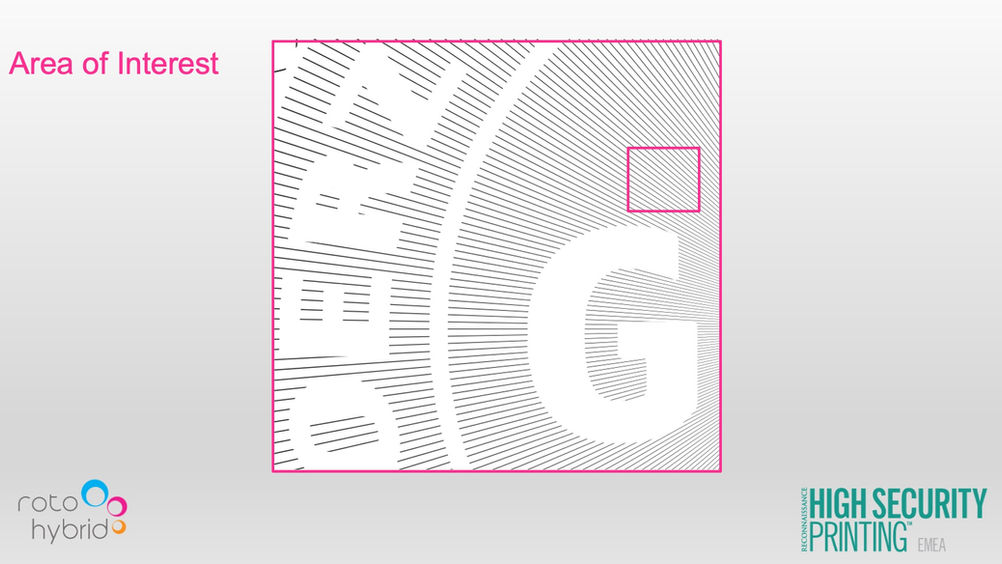

Increased Gravure Printed Security

Black Diamond allows the finest Gravure security features to be printed.

Previously, chromium based technologies struggled to print at this scale but Black Diamond's homogenous coating, not only replicates the engravings, it also provides improved release of the security inks, to deliver a consistent and accurate print, desired by Bank Note printers worldwide.

Outstanding Wear Resistance

Black Diamond provides significantly extended service life, to Gravure Security Cylinders.

We believe, there is no other gravure technology in the marketplace, that can deliver the outstanding quality of print, in combination with extended cylinder wear resistance.

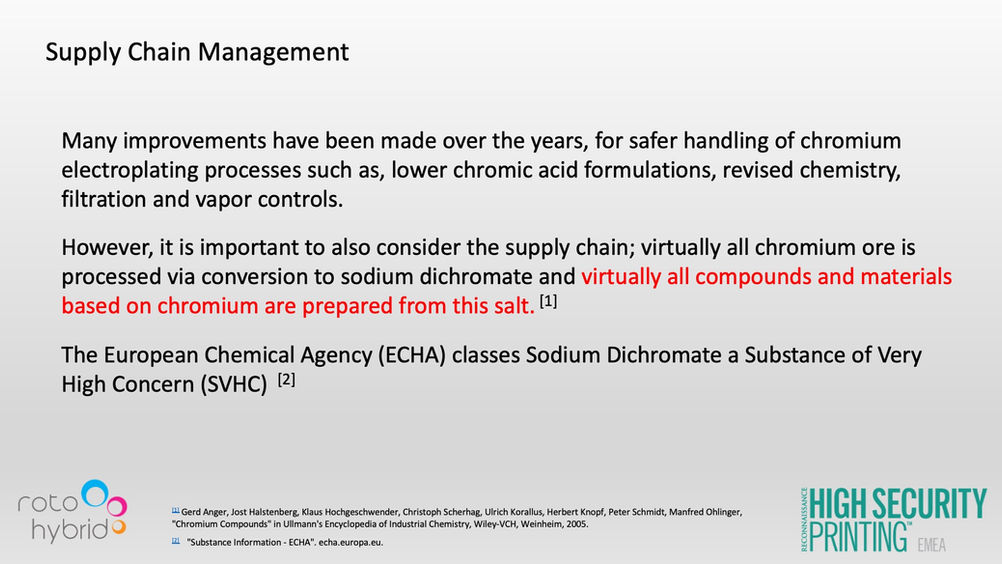

Environmentally Friendly

Black Diamond coating is none toxic, lower in energy use & CO2 per cylinder and kinder to the Environment.

It contains no Sodium Dichromate, derived chromic acid chemistry. Unlike Chromium, it is not considered a substance of very high concern (SVHC).

Lower Total Cost of Ownership

Due to the longer print service life, the total cost of ownership is less than using the multiple chromium cylinders that would otherise have been used.

Press stoppages due to worn out Gravure cylinders are greatly reduced and the easy clean surface results in less downtime due to print degradation failures

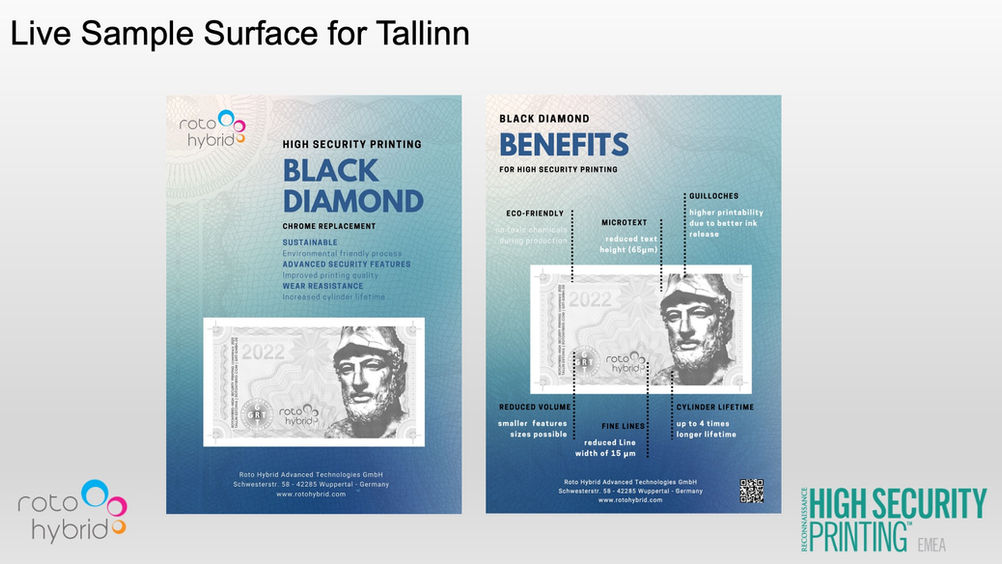

Black Diamond for Document & Security Print

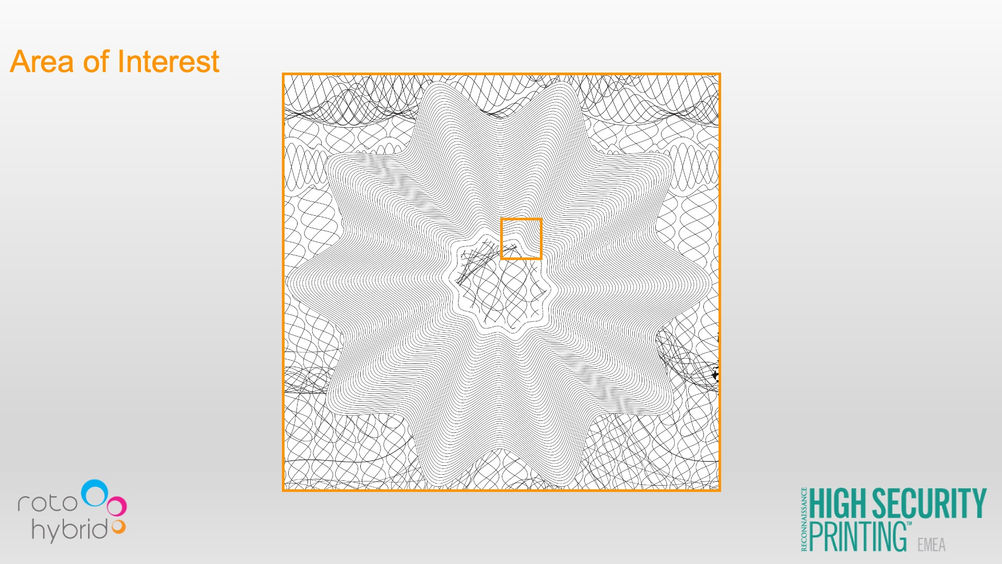

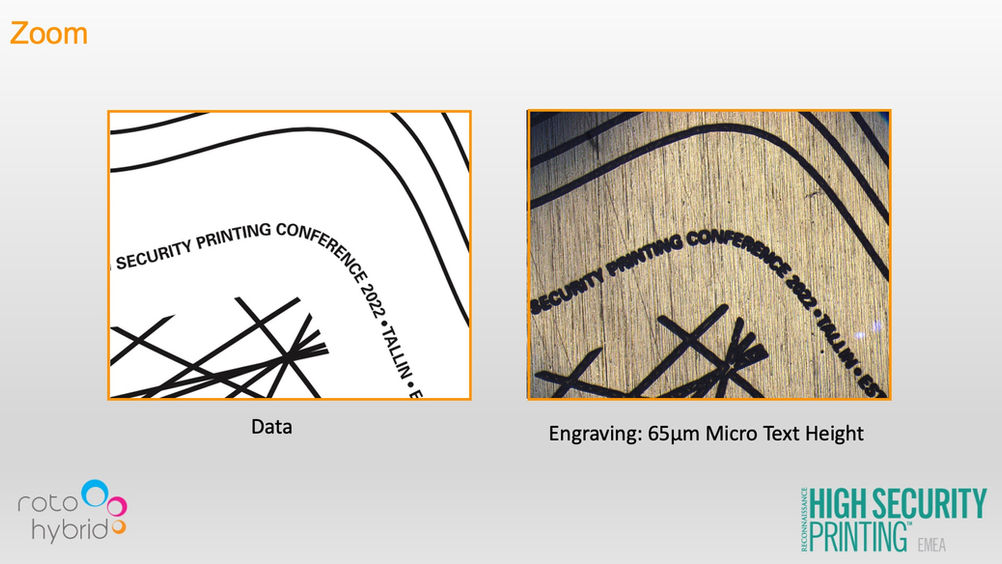

Demo Bank Note Trial with GRT, Germany

Roto Hybrid worked closely with GRT, Germany to create an array of features, that showcase the strengths of Black Diamond Gravure Security.

Proven Superiority

Roto Hybrid Advanced, are in advanced testing with several leading security companies and institutions.

Naturally, we are not allowed to present security company results. However, we have scientific evaluation, from a leading Independent University:

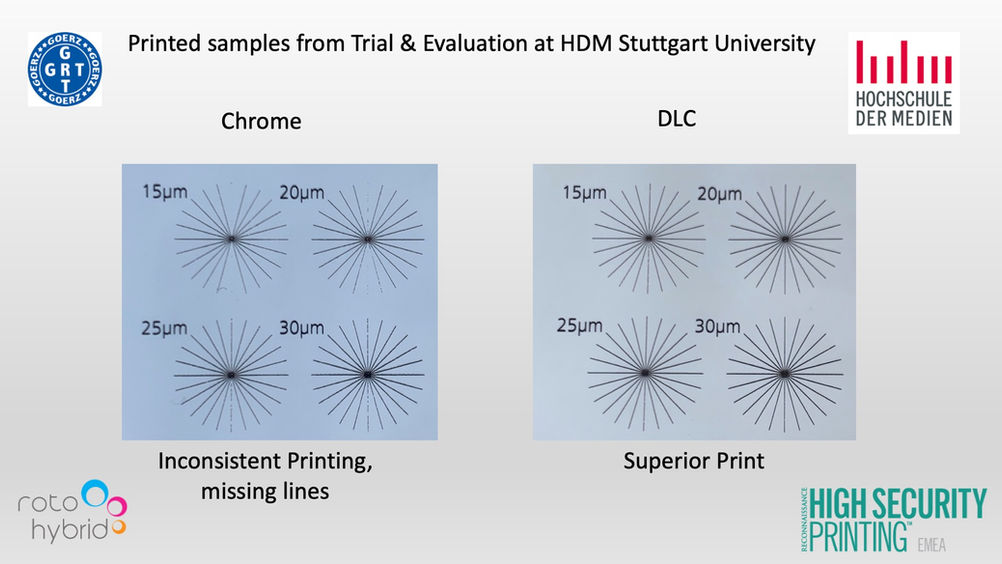

HDM UNIVERSITY STUTTGART SCIENTIFIC PAPER

"Comparison of the performance of DLC to chromium as wear resistance layer on a gravure cylinder for printing fine line structures"

Assessments from HDM Stuttgart paper:

"The improvements were very significant.”

“far superior’ in all print orientations on the substrate.”

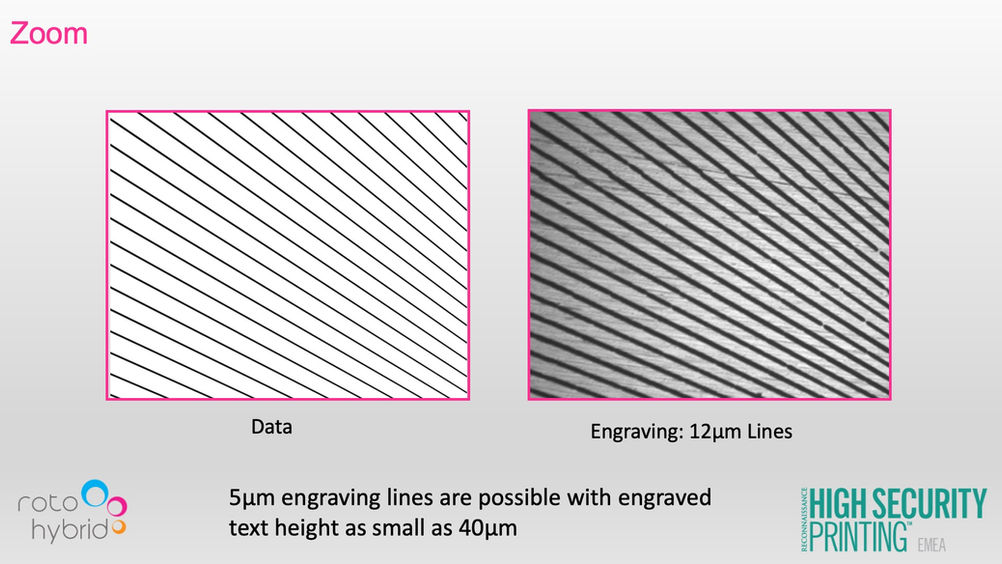

“With DLC line continuation in our trial down to 15µm.”

“Superior continuous Tone to the smallest dots.”

“DLC outperformed chrome in every test.”

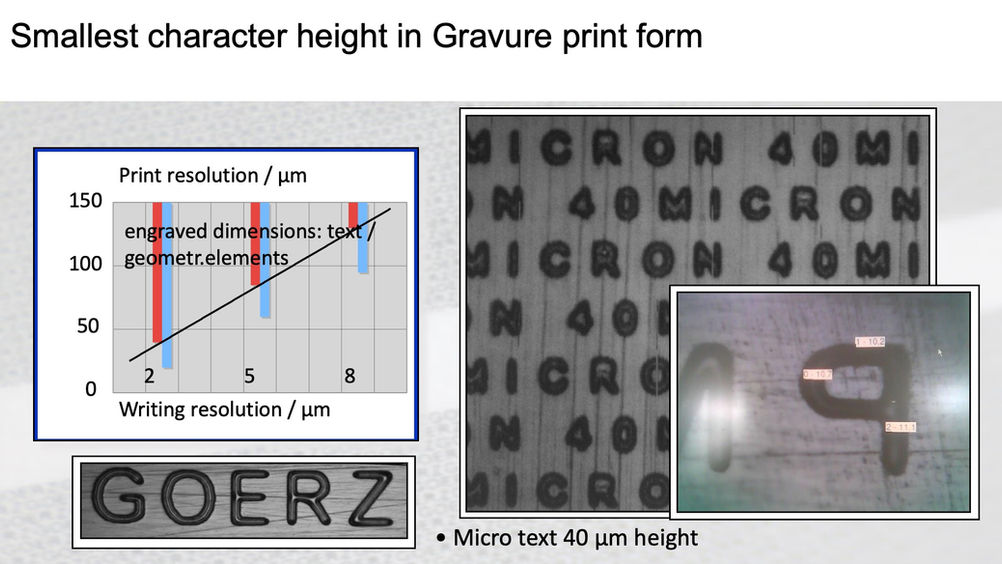

GRT Engraved 12μm Lines

GRT Engraved 35μm

Micro Text Height

Wide range of coating specifications

Due to their diverse properties, hard carbon-based tribological layers (DLC layers) :

Have an extremely wide range of applications. Wherever low friction is important, such layers offer great benefits, as they can significantly reduce friction and thus wear.

By specifically influencing the surface properties, gravure specific DLC, can be precisely adjusted to the respective requirement profile and thus optimised application-specifically.

Can be adjusted in a composition of components, for best fit to your technical requests